Neutron and X-ray Supermirrors can be:

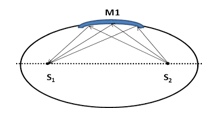

•Flat, spherical

–Can be ground and polished with a hard lap

•Two-dimensional curve

–Can be polished flat and then bent to a curve

•Three-dimensional curve

–Requires CNC grinding, and polishing

–Final polish requires a soft-lap, often by hand

Gas Cluster Ion Beam Technology

•A new technology of nano scale smoothing and alteration of surfaces

•Can be thought of as a nano-scale “sand blaster” that smooths a surface by the overlapping impacts of many small projectiles

–Particles are nano scale

–Hypervelocity

GCIB/ANAB is a large toolbox for modifying surfaces at the nanoscale

•GCIB/ANAB parameters

-Cluster composition (Ar, N2, O2, H2, NF3, B2H6 ………)

-Average cluster size (10,000 monomers is typical)

-Average cluster velocity (1-10 km/s, 1-10 eV/monomer are typical), can be varied from gentle cleaning, compacting at low velocity, up to aggressive etching and chemical alteration at high velocities.

-Impact angle

-typically less than ± 20 degrees from normal or at grazing incidence

-Dose

-Large doses such that every point on the surface are struck many times are easily achieved

Some applications and benefits of GCIB/ANAB Technology

•Very fine atomic level polishing that removes fine residual scratch marks produced by mechanical polishing

•Works equally well on curved surfaces as flat surfaces

•Can be used on any material, both conducting and non-conducting

•No Mechanical Contact

–Can be used on very thin films

•Can be used for nano/micron scale corrective etching to improve figure

•GCIB assisted deposition has been demonstrated to improve density and consistency of thin films